Membranen

Unsere Wetterschutzmembrane aus PVC-beschichtetem Polyestergewebe überzeugt durch hohe Reißfestigkeit, UV- und Witterungsbeständigkeit sowie TRAS120-Konformität. Maßgefertigte Handarbeit und zwei unabhängige Schweißverfahren gewährleisten doppelte Sicherheit.

Die weiterentwickelte neueste Generation der umweltfreundlichen Gasspeichermembrane aus PE zeichnet sich durch hohe Flexibilität, geringe Durchlässigkeit und eine signifikante Verringerung der Geruchsemissionen aus.

Wärmeschutzmembrane

Unsere patentgeschützte Wärmeschutzmembrane verhindert die ständige Aufwärtsbewegung des Gases und reduziert so Wärmeverluste bis zu 30 %. Das Gasspeichervolumen bleibt weiterhin uneingeschränkt nutzbar, wodurch Energie und Kosten gespart werden, was sich schnell auszahlt und umweltfreundlich ist.

Unterkonstruktion

Unsere Gurt-Netz-Unterkonstruktion vereint Zuverlässigkeit und Langlebigkeit: Die Unterkonstruktion ist vom Befestigungssystem entkoppelt, was nicht nur Flexibilität sondern auch Sicherheit bei Wartungs- und Montagearbeiten bietet. Die Funktion der Unterkonstruktion bleibt auch nach dem Öffnen der Membrane erhälten. Das robuste Unterspannnetz verhindert direkten Kontakt der Membrane mit dem Substrat. Hochwertige V4A-Edelstahlteile und biogasbeständige Materialien garantieren eine maximale Nutzungsdauer.

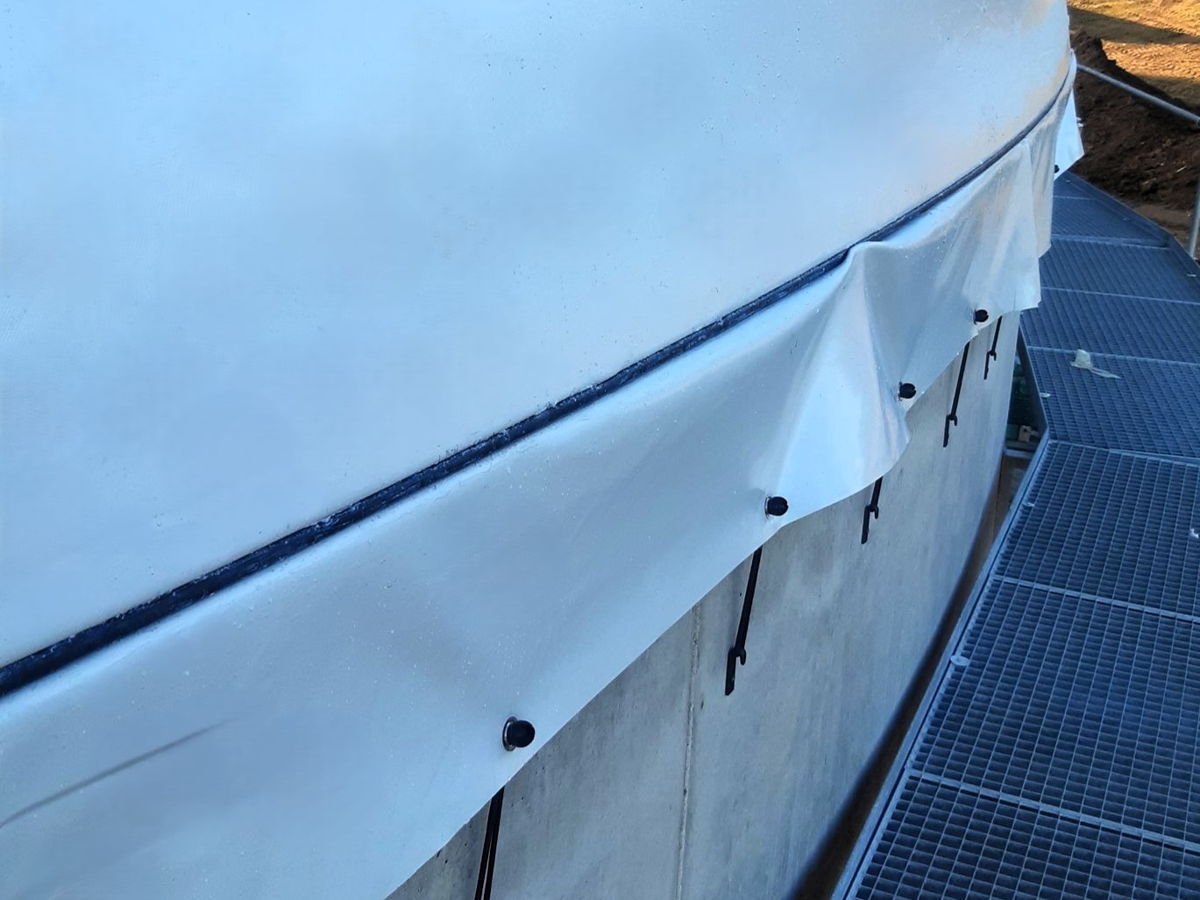

Befestigungssystem

Das Baur Doppelflachprofil aus Edelstahl ist durch seine spezielle Bauart die passende Lösung für jeden Behälter. Diese Konstruktion gewährleistet eine optimale Gasdichtigkeit, bietet eine hohe Stabilität und Langlebigkeit. Dank ersetzbarer Schraubanker ist es wartungsfreundlich und kostensparend.

Das Baur Edelstahl U-Profil mit Klemmschlauchsystem bietet eine sichere, wartungsfreundliche und langlebige Lösung zur Folienbefestigung. Das Zwei-Kreislaufsystem ermöglicht schnelles Öffnen und Schließen, während die integrierte Druckluftüberwachung für optimale Betriebssicherheit sorgt. Dank Glykolzugabe bleibt das System auch bei niedrigen Temperaturen frostsicher und zuverlässig.

Zu- und Abluftsystem

Unsere ATEX-zertifizierten Stützluftgebläse bieten die perfekte Lösung für den optimalen Betrieb Ihres Doppelmembrangasspeichers. Wir planen die Auslegung der Stützluftversorgung individuell nach den Anforderungen Ihrer Biogasanlage. Dank umfangreicher Lagerhaltung garantieren wir eine schnelle Verfügbarkeit verschiedener Gebläsetypen.

Unser Zu- und Abluftsystem sorgt für Sicherheit und Effizienz in Ihrem Doppelmembrangasspeicher. Sie ermöglichen eine präzise Einstellung des Stützluftdrucks und gleichen Druckveränderungen aus.

Füllstandsanzeige

Zur effizienten Anlagensteuerung integrieren wir die für Sie passende Messtechnik zu Ihrem Gasspeichersystem. Zu den möglichen Varianten der Gasfüllstandmessung mit Signalbereich 4-20 mA bieten wir an:

- Füllstandmessung mit Seilzugsystem und Niveaumessstab

- Füllstandsmessung mit Lasersensor

- Füllstandmessung mit hydrostatischem Sensor

Über- und Unterdrucksicherung

Unsere Über- und Unterdrucksicherung im Tauchtassenprinzip schützt Ihren Doppelmembrangasspeicher zuverlässig. Wir bieten verschiedene Ausführungen für unterschiedliche Betriebsdrücke und Volumenströme an. Eine optional verfügbare Begleitheizung und Signalisierung des Überdrucks sorgt für einen sicheren, störungsfreien Betrieb.

Mittelstütze

Wir bieten V4A-Mittelstützen, Mittelstützenverlängerungen oder formgerechte Kopfteile für betonierte Mittelstützen oder Holzstützen – flexibel und passgenau für Ihren Doppelmembrangasspeicher. Stabilität und Qualität aus einer Hand!

Gurtüberspannung

Unser patentiertes Gurtüberspannsystem entlastet gezielt die Wetterschutzmembran, indem es zusätzliche Lasten aufnimmt und gleichmäßig verteilt. Die Anordnung der Gurte verringert gezielt die Belastung der Membrane an den Schlüsselstellen, was die Stabilität des Gasspeichers bei erhöhten Windlasten und höheren Betriebsdrücken deutlich steigert. Dies führt zu einer verbesserten Betriebssicherheit und höheren Effizienz.

Serviceöffnung / Einstieg

Unsere eigens entwickelte Serviceöffnung für Doppelmembrangasspeicher ermöglicht einen schnellen und witterungsunabhängigen Zugang in den Stützluftraum für Wartungsarbeiten und Überprüfungen. Eine Öffnung des Membran-Befestigungssystems ist dabei nicht nötig.